UNWINDER & WEB GUIDING

Large Unwind for rolls with diameter of maximum 1200mm with reel lift standard included.

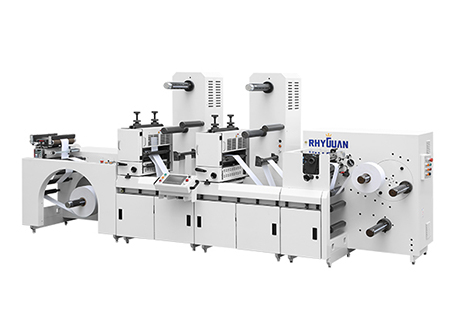

Rhyguan LG-420 Multi-Functional Blank Label Die Cutting Machine is a newly need mainly for big blank label orders, Cost-efficient high speed full rotary die cutting solution.

Features full rotary die cutting, providing high-quality cutting of film and label stock material. Options inline combination available with laminator and slitter.

| LG-420 | AVAILABLE WIDTH: 420MM/520MM |

| Max Die-cutting speed (full-rotary) | 200m/min |

| Max Unwinder dia. | 1200mm |

| Max Rewinder dia. | 700mm |

| Min Slitting width | 16mm |

| Accuracy of Register | ±0.15mm |

| Adjustable anvil( option) | Available from various manufacturers |

| Standard Magnetic Cylinder | 60-160T |

| Registration | Mark Sensor |

| Dimension | 3850×1550×1550mm |

| Weight | 2550KGS |

Large Unwind for rolls with diameter of maximum 1200mm with reel lift standard included.

Pre-release function, to allow for better separation of the matrix after die-cutting.

Independent Servo driven full rotary die-cutting unit, with Z60-160 die-cut cylinder and anvil and counter pressure cylinder. Standard gap = 0.48mm. Full rotary: repeat length: 190.5mm-508mm. Option with snowball matrix rewinder.

Optional standard 6 shear slitter or razor blade slitter. Easy to install. Features a standard high pressure waste suction system.

High speed rotary cut-sheet module with a conveyor belt enable sheet cutting and collations. This can be upgraded with an automatic stacking unit and combined with single and dual rewind options for optimal flexibility.

Optionally add a 4 spindle fully automatic non-stop turret rewinder with automatic hotmelt glue injectors.

Rhyguan is a leading manufacturer dedicating in label finishing machines, get your suitable converting solutions here:

The news column of Zhejiang Rhyguan Machinery Co., Ltd. introduces you to the knowledge and solutions for inspecting slitting and rewinding machines, digital finishing machines, rotary die-cutting machines, flatbed die-cutting machines, laser die-cutting machines, and inkjet machines.

In industries that rely on roll goods—such as flexible packaging, labels, non-wovens, and advanced films—maintaining flawless quality and high efficiency is paramount. This is where the Automatic Inspection Slitter Rewinder Machine becomes a game-changer.

A rotary cutter is a powerful machine used for cutting materials in a continuous, rolling motion. Unlike a guillotine cutter that chops down, a rotary cutter uses a circular blade that rolls over the material, shearing it with exceptional accuracy and clean edges. It is a fundamental piece of post-press equipment, essential for finishing products after they are printed, coated, or manufactured.

For anyone in label production, knowing how key equipment operates helps with smart decisions—whether choosing tools or fixing small issues. The Rotary Die Cutting Machine is a core tool for efficient label shaping and finishing. Let’s explain its working principle simply and clearly.