In the dynamic realm of manufacturing and production, rotary die cutting machines have emerged as indispensable tools, offering precise and efficient cutting solutions across a wide array of industries. These machines are designed to cut, crease, emboss, and perforate various materials, transforming them into the desired shapes and forms with high accuracy. From the packaging industry to the production of labels, textiles, and medical devices, rotary die cutting machine solutions play a crucial role in enhancing productivity, reducing costs, and ensuring product quality. This article will delve into the world of rotary die cutting machines, exploring their working principles, different types of solutions available, and the benefits they bring to modern manufacturing processes.

A rotary die cutting machine operates on the principle of using a cylindrical die (rotary die) that rotates in tandem with an anvil cylinder. The material to be cut, which can range from paper, cardboard, plastics, and rubber to fabrics and foams, is fed between the die and the anvil. As the die rotates, the cutting blades or knives on its surface press against the material, cutting through it with the assistance of the anvil. This continuous rotational motion allows for high - speed production, making rotary die cutting machines highly efficient for mass - manufacturing applications.

The rotary die itself is a key component, and it can be customized according to the specific cutting requirements. Dies can be made from various materials such as steel, tungsten carbide, or even flexible materials for more intricate cutting tasks. The design of the die determines the shape and size of the final product, and advanced computer - aided design (CAD) and computer - aided manufacturing (CAM) technologies are often used to create precise and complex die designs.

Packaging Industry

In the packaging industry, rotary die cutting machines offer a multitude of solutions. For the production of cartons and boxes, these machines can create clean, accurate cuts and creases, ensuring that the packaging is not only aesthetically pleasing but also structurally sound. High - speed rotary die cutters can handle large volumes of cardboard, enabling manufacturers to meet the demands of the market quickly. Additionally, rotary die cutting allows for the creation of unique packaging shapes, such as die - cut windows, handles, and interlocking tabs, which can enhance the visual appeal and functionality of the packaging.

For flexible packaging materials like plastic films, rotary die cutting machines can produce precisely cut pouches, bags, and labels. The machines can be equipped with features such as servo - driven systems for better control over the cutting process, ensuring consistent cut quality even for complex shapes. This is crucial in the food and beverage, cosmetics, and consumer goods sectors, where packaging needs to be both attractive and functional.

Label and Printing Industry

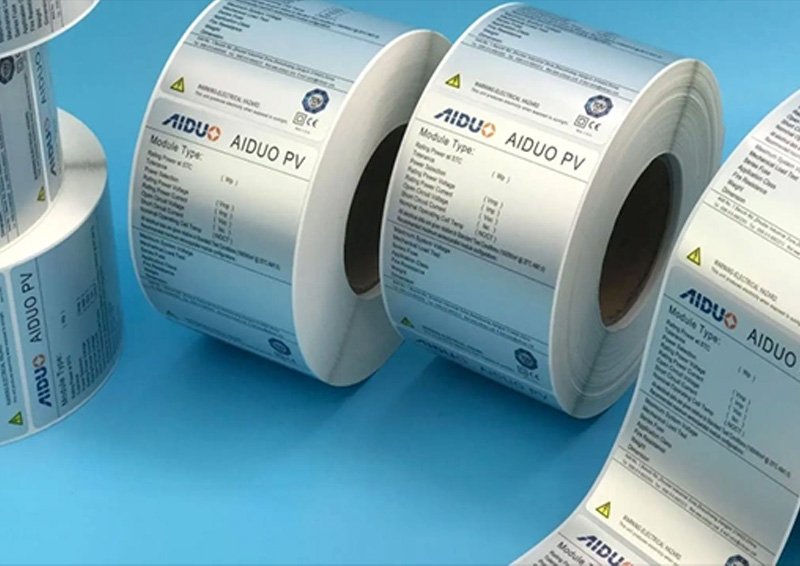

In the label and printing industry, rotary die cutting machines are essential for producing custom - shaped labels. Whether it's for product identification, branding, or promotional purposes, these machines can cut labels from rolls of adhesive - backed materials with great precision. They can handle a variety of label materials, including paper, polyester, and vinyl.

Rotary die cutting also enables the creation of kiss - cut labels, where only the top layer of the label material is cut, leaving the backing intact. This type of cutting is ideal for applications where the labels need to be easily peeled off and applied. Furthermore, the machines can perform additional operations such as perforating labels for easy tearing or embossing them for a more premium look.

Textile Industry

In the textile industry, rotary die cutting machines are used to cut fabrics into specific shapes for clothing, upholstery, and other textile products. These machines can handle different types of fabrics, from delicate silk and lace to heavy - duty denim and canvas. Rotary die cutting ensures clean, straight cuts, reducing fabric waste and improving the overall efficiency of the cutting process.

For applications such as cutting out fabric pieces for garments, the machines can be programmed to cut multiple layers of fabric simultaneously, significantly increasing productivity. Additionally, rotary die cutting can be used to create decorative elements on textiles, such as cut - out patterns or scalloped edges, adding value to the final product.

Medical Device Industry

In the highly regulated medical device industry, precision and hygiene are of utmost importance. Rotary die cutting machines provide solutions for cutting medical materials such as surgical drapes, wound dressings, and medical tapes. These machines can be designed to meet strict cleanroom requirements, ensuring that the cutting process does not contaminate the medical products.

The ability to make precise cuts is crucial in the medical field, as even the slightest deviation can affect the functionality and safety of the device. Rotary die cutting machines can be equipped with advanced sensors and control systems to monitor and adjust the cutting process in real - time, ensuring consistent quality and accuracy.

While rotary die cutting machines offer numerous advantages, there are also challenges that manufacturers may face. One common challenge is the wear and tear of the cutting blades. Over time, the blades can become dull, leading to poor cut quality and increased production downtime. To address this issue, many manufacturers opt for high - quality blades made from durable materials and implement regular maintenance and blade - changing schedules.

Another challenge is the setup time for different cutting jobs. Changing the die and adjusting the machine settings for a new product can be time - consuming. However, modern rotary die cutting machines often come with quick - change die systems and automated setup features, which significantly reduce the setup time and increase the machine's flexibility.

The future of rotary die cutting machine solutions looks promising, with continuous advancements in technology. One trend is the integration of automation and robotics. Automated rotary die cutting machines can operate with minimal human intervention, reducing labor costs and improving production efficiency. These machines can be programmed to perform complex cutting tasks, adjust settings automatically, and even monitor their own performance.

The use of advanced materials and coatings for dies is also on the rise. New materials are being developed to increase the durability and cutting performance of the dies, while special coatings can reduce friction and improve the release of the cut materials. Additionally, the development of smart sensors and Internet of Things (IoT) technology will enable real - time monitoring and predictive maintenance of rotary die cutting machines, further enhancing their reliability and reducing downtime.

In conclusion, rotary die cutting machine solutions have revolutionized the manufacturing industry, providing efficient, precise, and versatile cutting solutions for a wide range of applications. As technology continues to evolve, these machines will become even more advanced, meeting the growing demands of modern manufacturing and opening up new possibilities for product design and production. Whether it's in packaging, labeling, textiles, or the medical field, rotary die cutting machines will remain an essential part of the production process, driving innovation and excellence.

● Another PLUS-330 Machine Installed in Latin America

● Another Two Installations at Customers’ Site

● Rhyguan Plus Month

● Top security level in Rhyguan

● Another Rotary Die-cutting Installation at Cutsomer’s Site

● Perfect Factory Acceptance Testing for Label Inspection Machines

● New Rhyguan Factory Preview

● Rhyguan Industrial 4.0 Live Presentation