As brands increasingly demand unique, irregular-shaped labels (e.g., custom gift boxes, 3D stickers), the challenge of cutting these designs precisely grows. Traditional cutting methods often struggle with thick materials or complex shapes. Here’s why flatbed die cutting machines emerge as a go-to solution for specialty label production.

Flatbed die cutters excel in specific scenarios where precision and flexibility matter most.

Labels on cardboard, textured paper, or rigid films need consistent pressure to avoid tearing. Flatbed systems press the die evenly across the entire label surface, ensuring clean cuts—even for thick substrates that rotary cutters (designed for thin rolls) might struggle with.

Logos with complex edges, die-cut stickers, or special-shaped (irregular) packaging labels rely on custom dies. Flatbed machines work with specialized dies to recreate precise shapes, from delicate curves to multi-layered designs, without compromising accuracy.

For limited-run projects (e.g., seasonal promotions, boutique brands), flatbed cutters shine. Swapping dies is faster than reconfiguring rotary systems, making them cost-effective for low-volume, high-customization orders.

What makes flatbed die cutters so effective at precision cutting?

Unlike rotary cutters (which apply pressure in a rolling motion), flatbed machines use a stationary, even press. This eliminates “pressure gaps,” resulting in smooth, fray-free edges—critical for premium labels.

Flatbed systems support a wide range of die types, including steel-rule and laser-cut dies. This adaptability lets manufacturers create unique dies for any shape, then reuse them for future orders—ideal for brands with signature label designs.

Flatbed and rotary die cutters serve different needs. Here’s how they compare:

Rotary: Best for high-volume, roll-fed labels (e.g., beverage bottles) thanks to continuous motion.

Flatbed: Slower but more flexible, prioritizing precision and customization over speed.

Rotary systems require expensive, custom-made cylindrical dies. Flatbed dies are more affordable and easier to swap, lowering upfront costs for small batches.

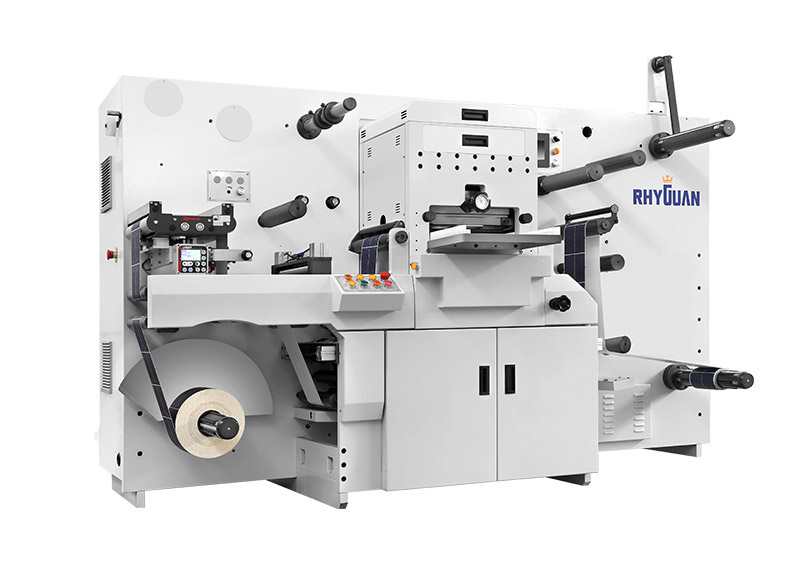

Rhyguan has over 15 years of experience in label finishing technology. We not only provide flatbed die-cutters, but also design solutions for specific industry challenges.

Rhyguan's systems can handle complex shapes and tight tolerances, supporting low-volume production without sacrificing quality. Whether it's luxury packaging or custom stickers, we ensure every cut matches the exact design.

Flatbed die cutting machines fill a crucial niche: precision cutting for thick, irregular, or low-volume labels. By prioritizing even pressure, custom die compatibility, and small-batch flexibility, they solve pain points traditional methods can’t. For brands and manufacturers, the choice comes down to needs: speed (rotary) or precision-plus-flexibility (flatbed).

If your labels demand intricate shapes, thick materials, or limited runs, a flatbed die cutter might be the missing piece in your production workflow.

● Another PLUS-330 Machine Installed in Latin America

● Another Two Installations at Customers’ Site

● Rhyguan Plus Month

● Top security level in Rhyguan

● Another Rotary Die-cutting Installation at Cutsomer’s Site

● Perfect Factory Acceptance Testing for Label Inspection Machines

● New Rhyguan Factory Preview

● Rhyguan Industrial 4.0 Live Presentation