UNWINDER & WEB GUIDING

Unwinder with closed-loop tensioncontrol. Electronic web guide withultrasonic edge guide sensor. 76mm air expanding mandrel. Maxdiameter 700 mm - 1000 mm rollcapacity.

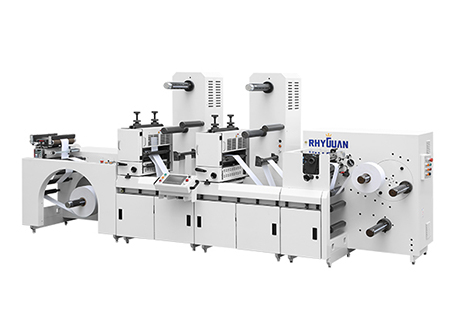

Rhyguan TOP-330-PLUS Varnishing & Die cutting Solution, features Winding, Cold Foiling, Super Varnishing, Flexo Printing(can do varnish and simple one-color printing), Semi-rotary Die-cutting, IML system, various Slitting, and Sheeting options. And many options such as Cororna, hotair, chiller, automatic slitting, and even inspection modules. Rhyguan lauched this very entry-level model for label digital finishing, can suit most of the end-customers use.

| TOP-330-PLUS | OPTION WIDTH 420MM/520MM |

| Max Web Width | 330mm |

| Max Die-cutting speed (full-rotary) | 110m/mim |

| Max Die-cutting Speed (semi-rotary) | 60m/min |

| Max Flexo Printing Speed | 110m/min |

| Accuracy of Flexo Register | ±0.15mm |

| Max Unwinder dia. | 700mm |

| Max Rewinder dia. | 700mm |

| Min Slitting width | 16mm |

| Accuracy of Adhesive Cutting | ±0.15mm |

| Accuracy of IML Cutting | ±0.25mm |

| Standard Magnetic Cylinder | 120T |

| Total Motor Power | 19KW ~ 21KW |

| Registration | Mark Sensor |

| Dimension | 3600×1260×1925mm |

| Weight | 3500 KGS |

Unwinder with closed-loop tensioncontrol. Electronic web guide withultrasonic edge guide sensor. 76mm air expanding mandrel. Maxdiameter 700 mm - 1000 mm rollcapacity.

lndependent, servo-driven fullrotary printing unit with autopre-positioning and registration.Offers reverse side printing. Printingrepeat lengths of 50 mm - 457 mm.

Cold-foil and super varnish withtwo pneumatic shafts and unwind/rewind.

lndependent and servo-driven.Repeat lenghts from 50 mm - 330mm for semi-rotary, and 190.5 mm-476.25 mm for full rotary. Magneticor solid/engraved cylinders.

IML die-cutting system designed foreasy installation and removal. Staticeliminator in label output collectiontable works with counter and stepless speed regulation.

Rewinder with closed-loop tensioncontrol system ensures continuousstable tension. 700 mm maximumrewind diameter.

Rhyguan is a leading manufacturer dedicating in label finishing machines, get your suitable converting solutions here:

The news column of Zhejiang Rhyguan Machinery Co., Ltd. introduces you to the knowledge and solutions for inspecting slitting and rewinding machines, digital finishing machines, rotary die-cutting machines, flatbed die-cutting machines, laser die-cutting machines, and inkjet machines.

A rotary cutter is a powerful machine used for cutting materials in a continuous, rolling motion. Unlike a guillotine cutter that chops down, a rotary cutter uses a circular blade that rolls over the material, shearing it with exceptional accuracy and clean edges. It is a fundamental piece of post-press equipment, essential for finishing products after they are printed, coated, or manufactured.

For anyone in label production, knowing how key equipment operates helps with smart decisions—whether choosing tools or fixing small issues. The Rotary Die Cutting Machine is a core tool for efficient label shaping and finishing. Let’s explain its working principle simply and clearly.

Many people know a Digital Finishing Machine works in post-print processing, but they often don't clarify which specific industries rely on it. This article breaks down the core industries that benefit from this equipment, explaining why it's a practical tool for meeting industry needs—not just a “nice-to-have."