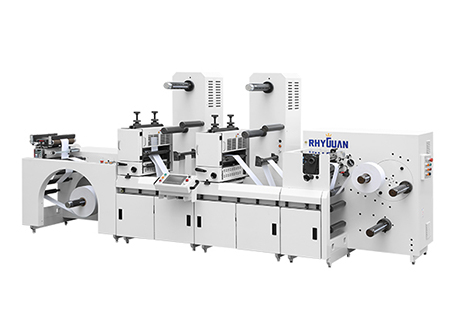

Rhyguan latest design of flexo and die-cutting machine to meet the increasingly changed labeling market, TOP-330-PLUS-3 is also fully servo driven, features Winding, Cold Foiling, Super Varnishing, Semi/full Flexo Printing, fast Semi-rotary Die-cutting (90m/min) and Slitting.

All Rhyguan TOP-PLUS series is designed for digitally controlling the servo engines as well, which provides synchronization across all servo engines with precision timings and accurate step-and-repeats. The result shows excellent tension control, a very smooth-running machine, and astonishing finishing quality.

The new design of Rhyguan TOP-330-PLUS-3 is much more compact than the TOP-330-PLUS-2, but it will still remain as much available as possible. Also, the control stations for the UV curing and the Corona are embedded inside the machine body, which reduces the machine's place in your factory to a minimum. Another change is Rhyguan increasing the limits of the max speed, making it much more productive for the big orders.

| TOP-330-PLUS-3 | AVAILABLE WIDTH:330MM/420MM |

| Max Web Width | 330mm |

| Max Die-cutting speed (full-rotary) | 110m/min (option 180m/min) |

| Max Die-cutting speed (semi-rotary) | 90m/min |

| Max Flexo Printin g speed (ful-rotary) | 110m/min |

| Max Flexo Printing speed (semi-rotary) | 60 m/min |

| Accuracy of Register | ±0.15mm |

| Max Unwinder dia. | 800mm |

| Max Rewinder dia. | 800mm |

| Sliting Precision | ±0.2mm(automatic)±0.15mm(shear)±0.15mm (razor) |

| Min Slit width | ≥ 18mm(automatic)≥16mm (shear)≥11mm(razor) |

| Accuracy of Adhesive Cutting | ±0.15mm |

| Corona (recommended option) | 6 electrodes. Control unit mounted inside machine |

| UV( recomme nded option) | Standard UV or LED UV curing.(control units) mounted inside machine |

| Adjustable anvil( option) | Available from various manufacturers |

| Registration | Mark Sensor |

| Dimension | 3650×1800×1800mm |

| Weight | 3600KGS |

Rhyguan is a leading manufacturer dedicating in label finishing machines, get your suitable converting solutions here:

The news column of Zhejiang Rhyguan Machinery Co., Ltd. introduces you to the knowledge and solutions for inspecting slitting and rewinding machines, digital finishing machines, rotary die-cutting machines, flatbed die-cutting machines, laser die-cutting machines, and inkjet machines.

A rotary cutter is a powerful machine used for cutting materials in a continuous, rolling motion. Unlike a guillotine cutter that chops down, a rotary cutter uses a circular blade that rolls over the material, shearing it with exceptional accuracy and clean edges. It is a fundamental piece of post-press equipment, essential for finishing products after they are printed, coated, or manufactured.

For anyone in label production, knowing how key equipment operates helps with smart decisions—whether choosing tools or fixing small issues. The Rotary Die Cutting Machine is a core tool for efficient label shaping and finishing. Let’s explain its working principle simply and clearly.

Many people know a Digital Finishing Machine works in post-print processing, but they often don't clarify which specific industries rely on it. This article breaks down the core industries that benefit from this equipment, explaining why it's a practical tool for meeting industry needs—not just a “nice-to-have."