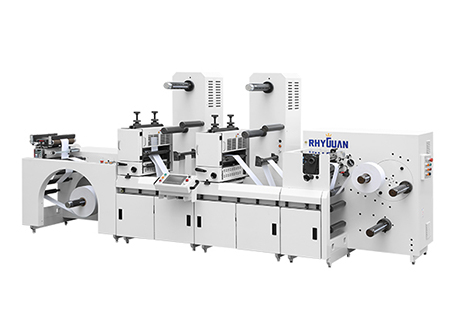

The Rhyguan PLUS-330/420 systems are modular in design, so that each machine can be tailored to meet your needs and create a clear, competitive advantage for your business.

Nearly all modules can be combined, and it is also possible to fit multiple flexo, screen or die-cut modules into one machine. Each module features independent tension control, and an independent step-and-repeat, with a sensor for re-registration. This creates maximum flexibility, more ways to optimize productivity and minimize tooling costs.

Also, The modern movable touchscreen user interface is operator friendly and easy to use.

All moudules following can be customized into one PLUS machine to help your business:

Rhyguan is a leading manufacturer dedicating in label finishing machines, get your suitable converting solutions here:

The news column of Zhejiang Rhyguan Machinery Co., Ltd. introduces you to the knowledge and solutions for inspecting slitting and rewinding machines, digital finishing machines, rotary die-cutting machines, flatbed die-cutting machines, laser die-cutting machines, and inkjet machines.

In industries that rely on roll goods—such as flexible packaging, labels, non-wovens, and advanced films—maintaining flawless quality and high efficiency is paramount. This is where the Automatic Inspection Slitter Rewinder Machine becomes a game-changer.

A rotary cutter is a powerful machine used for cutting materials in a continuous, rolling motion. Unlike a guillotine cutter that chops down, a rotary cutter uses a circular blade that rolls over the material, shearing it with exceptional accuracy and clean edges. It is a fundamental piece of post-press equipment, essential for finishing products after they are printed, coated, or manufactured.

For anyone in label production, knowing how key equipment operates helps with smart decisions—whether choosing tools or fixing small issues. The Rotary Die Cutting Machine is a core tool for efficient label shaping and finishing. Let’s explain its working principle simply and clearly.