DIGITAL INTERFACE

The Rhyguaninterface and documentation allows your pre-press software provider or any other IT system tointegratedinto the Rhyguan system.

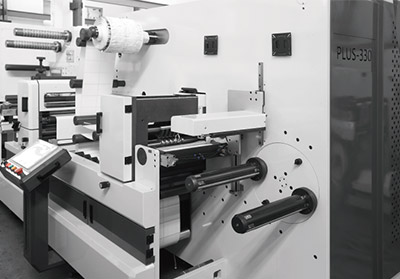

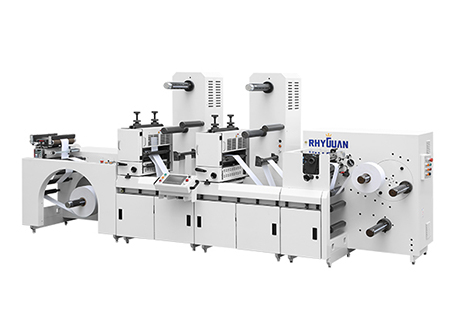

The PLUS330/420 is production machine with the latest technology. Each module is build around a thick solid steel frame, and features branded components inside. Configure either a classical finishing unit or a highly automated and networked unit in constant communication with your CRM/ERP system. And select from a wide range of label delivery options for flexibility and to meet the needs of your customers.

The Rhyguaninterface and documentation allows your pre-press software provider or any other IT system tointegratedinto the Rhyguan system.

Digital die-cutting with the same look and feel of a traditional die-cut. A dual row of plotter heads with utomatic calibration functions allow to fully digitally die-cut at a speed of upto 8m/min for standard jobs.

Digitally apply varnish and digital haptic effect with thickness upto 0.2mm, with high resolution Konica printheads. Standard one row of printheads, optionally two with each rowits own (or same) type of varnish for maximum flexibility. Automatic printhead adjustment.

Automatically positioned slitting knifes that are easy to controlform the user-interface,including edge-trimming.Maximum of 10 knifes allows for a wide range of slitting possibilities.Optionally add manualrazor blade also.

Servo driven rewinder for clockwise and anti-clockwise rewinding with stable and servo controlled tension. Possible to add automatically controlled differential rewind hafts.Possible to add a separate counter.

High speed rotary cut-sheet module with a conveyor belt enable sheet cutting and collations. This can be upgraded with an automatic stacking unit and combined with single and dual rewind options for optimal flexibility.

Semi-automatic 2-spindle turret which willturn automatically, and lower a pressure arm upon reaching the counter set. Simple, effective and highly productive.Suitable for clock-wise and anti-clockwise rewinding.

Rhyguan is a leading manufacturer dedicating in label finishing machines, get your suitable converting solutions here:

The news column of Zhejiang Rhyguan Machinery Co., Ltd. introduces you to the knowledge and solutions for inspecting slitting and rewinding machines, digital finishing machines, rotary die-cutting machines, flatbed die-cutting machines, laser die-cutting machines, and inkjet machines.

A rotary cutter is a powerful machine used for cutting materials in a continuous, rolling motion. Unlike a guillotine cutter that chops down, a rotary cutter uses a circular blade that rolls over the material, shearing it with exceptional accuracy and clean edges. It is a fundamental piece of post-press equipment, essential for finishing products after they are printed, coated, or manufactured.

For anyone in label production, knowing how key equipment operates helps with smart decisions—whether choosing tools or fixing small issues. The Rotary Die Cutting Machine is a core tool for efficient label shaping and finishing. Let’s explain its working principle simply and clearly.

Many people know a Digital Finishing Machine works in post-print processing, but they often don't clarify which specific industries rely on it. This article breaks down the core industries that benefit from this equipment, explaining why it's a practical tool for meeting industry needs—not just a “nice-to-have."